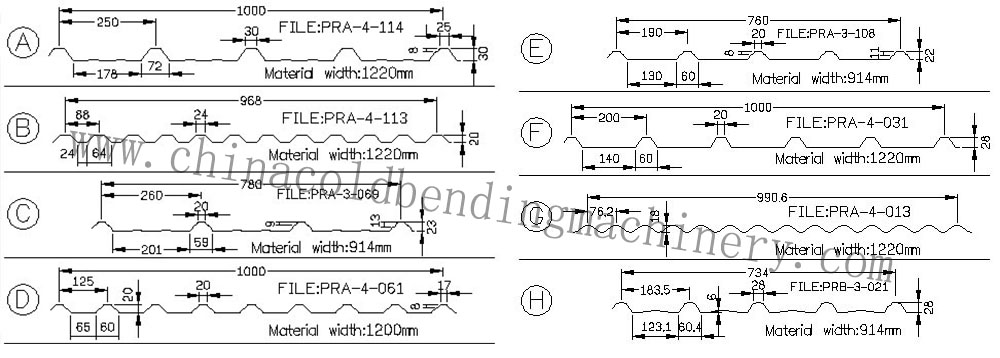

The double layer roofing sheet roll forming machine has the following advantage :

- Adopt the guider pillar and motorized cutings. This design make our machine stable fast cutting and long service life.

- Save cost for clients. Current Capital is so important to run a business.

- .Save Working Space.The workshop is not big enough to install two sets of roll forming machine for some of customers.For this situation, double layer roll forming machine is your best choice. You only need one space of machine to produce two types of profiles.

What make the our machine different from other company ? Details .

- We persist on that each factory should put quality at the first place . We spend time and money on developing how to make our roofing sheet roll forming machine much more accurate , automatic and high quality .So we treat everything details of the machine strickly .

- Shaft and rollers are the most important parts for the roll forming machine . We use Cr12 steel with quenched treatment to make sure the roller more stronger and not scratch the surface of the panel and cutter more harder and long lived .

- Steel Plate welded and guide pillar screwed . Two cylinder for cutting balance and freely . Cr12 Mov cutting blade with treatment for long life . When in automatic production , the machine stop to post and post to cut . We can also adopt servo-tracking cutting system of non - stop cutting for your special requirements .

- Adopt internation PLC brand , such as Delta , Panasonic . Cutting length is controlled by high precision Omron counter . Excellent touch - screen with easy operation and good understanding for workers .

Company information

Kaiyite machinery is a leading manufacture of roll forming machine . We know well the particular requirements for the customers from different countries , and have an outstanding export team who will take your requests . Our experts and skilled workers complete the work with great precision .

We provide an extensive line of products , including roller shutter door roll forming machine ,door frame machine, roof and wall panel roll forming machine , double layer roll forming machine ,floor deck roll forming machine ,C / Z / U Purlin Roll Forming Machine , stud and track roll forming machine , ridge cap roll forming machine , downspout pipe roll forming machine , shearing machine and bending machine , slitting and cutting machine .

How to install the galvanized double layer roll forming machine ?

Please install roll forming machine in one level , put coil into the decoiler , add hydraulic oil into hydraulic oil pump ,it is 40# oil . PLC need connect one line of wire , and hydraulic oil tube , then you can try to let the machine working .

If you donot know how to debug and operate the machine , we can provide the perfect after sale service for you .

For our company, there is no problem for us to dispatch technicians abroad, and provide technical support for the whole life of our machine. Also I have enough patience and experience to help my customers to solve the problems occurred during using machine .