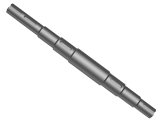

Mining Steel Idler Roller Spare Parts

Basic Info

Model No.: Mining Steel Idler

Product Description

The main function of a bulk material handling system is to continuously transport and supply bulk materials to units in processing plants. Secondary functions include storage and blending. One of the most prevalent equipment types in bulk material handling is a belt conveyor. They are used n many industries – such as chemical, cement, food, biomass and mining. Mining conveyors are always work in dusty harsh environment, spare parts for mining idler, particularly bearing for idler roller, need high quality and good anti seizeing performance. XKTE specializes in ball beairng for idler roller and roller bearing for pulley.

1. Conveyor Idler Tube or shell.

The Shells are made from Steel Tube with close tolerance ensuring smooth, Shock free and eccentricity free running with minimum dimensional run out, smallest rotating weight of rollers requires low horse power, thereby conserving power and energy due to lowest possible dynamic friction.

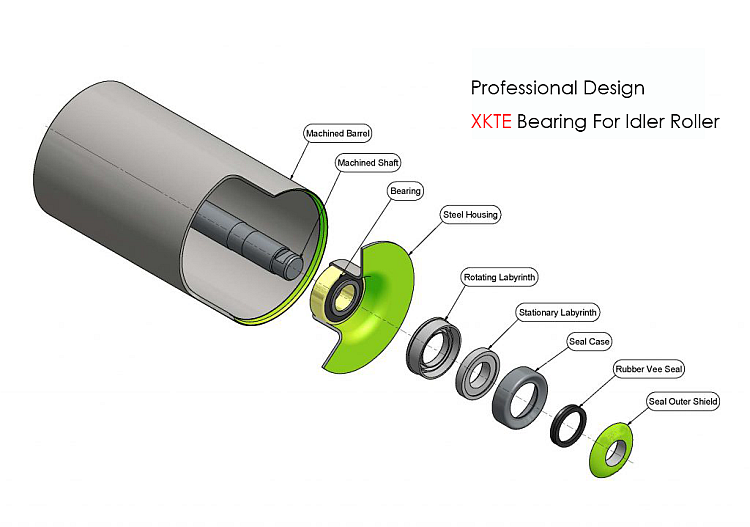

2. Seals

Conveyor idler Seals should be multi labyrinth type to prevent ingress of dirt, air and moisture.

The outer seal should be corrosion resistant.

3. Bearing housing are formed from strip steel deep pressed in automatic presses machine, this tolerance allowing a perfect match between the bearing and the relevant parts of the sealing.

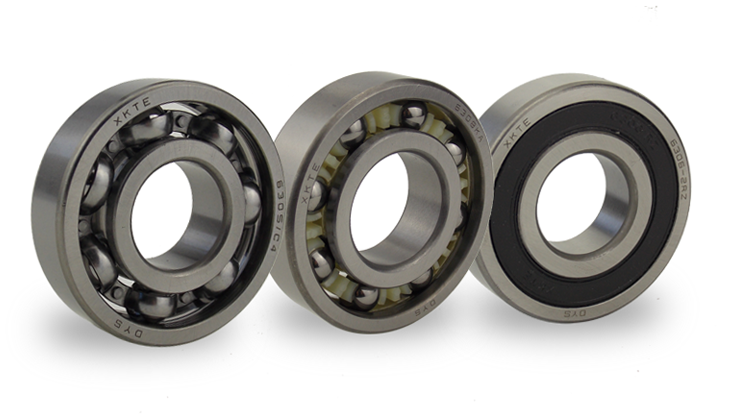

4. Bearing.Large clearance C3/C4 serials deep groove ball bearings, reinforced cage with big rivet, thick inner ring and outer ring. usually use double sealed structure to improve the water and dust proof ability.

Unique Design Seize-Resistant Deep Groove Ball Bearings: 6200 series-6300 series

1. KA/TN/TN9 nylon retainer Type

2. Open Type

3. Sealed Type

4. CSK series One way clutch bearing

Other Main Products for idler:

6200/6300 series deep groove ball bearing

6200/6300 series ball bearings are well suited for low to heavy radial loads and can be configured for various application speeds and running precision requirements. Reinforced iron Retainer, Super-finished deep groove, smooth race, thicker inner and outer ring.

| 6200/6300 Series Deep Groove Ball Bearing | |||||||

| Model | Bore Size(mm) | Outer Diameter(mm) | High(mm) | Weight(kg) | ball no. | Cr(kN) | Cor(kN) |

| 6204 | 20 | 47 | 14 | 0.106 | 8 | 12.8 | 6.65 |

| 6205 | 25 | 52 | 15 | 0.128 | 9 | 14 | 7.85 |

| 6305 | 25 | 62 | 17 | 0.232 | 7 | 20.6 | 11.3 |

| 6306 | 30 | 72 | 19 | 0.346 | 8 | 26.7 | 15 |

| 6307 | 35 | 80 | 21 | 0.457 | 8 | 33.4 | 19.3 |

| 6308 | 40 | 90 | 23 | 0.639 | 8 | 40.8 | 24 |

| 6309 | 45 | 100 | 25 | 0.837 | 8 | 52.8 | 31.8 |

| 6310 | 50 | 110 | 27 | 1.082 | 8 | 61.8 | 38 |

| Material Chrome Steel GCr15 | |||||||

5. Shaft: Shaft is formed from cold drawn round bar and calibrated to ISO to ensure precise assembling of bearing.

Conveyor Idler Roller Size:

| Standard Diameter | Standard Inner Diameter(mm) | Length scope(mm) | Bearngs Type | |

| mm | Inch | (Min-Max) | ||

| 89 | 3 1/3 | 60/50 | 170-3400 | 6204 |

| 102 | 4 | 76 | 170-3400 | 6204 6205 |

| 108 | 4 1/4 | 89/76/60 | 170-3400 | 6204 6205 |

| 114 | 4 1/2 | 89/76 | 170-3400 | 6204 6205 |

| 127 | 5 | 89 | 170-3400 | 6204 6205 |

| 133 | 5 1/4 | 89/70/63.5 | 170-3400 | 6204 6205 |

| 140 | 4 1/2 | 89 | 170-3400 | 6204 6205 |

| 152 | 6 | 108/76 | 170-3400 | 6204 6205 6206 6305 6306 |

| 159 | 6 1/4 | 108 | 170-3400 | 6204 6205 6206 6305 6306 |

| 194 | 7 5/8 | 159/133 | 170-3400 | 6205 6206 6305 6306 6307 6308 |

Features:

Support the return belt

Excellent roundness, good dynamic balancing

Smooth operation, easy replacement

Long service life, maintenance-free

Special: XKTE - Ball Bearings and Rolling Bearings in Conveyor Technology

XKTE is the specialist in rolling bearing technology for the mechanical application of continuous conveyors.

Whether bulk or general cargo conveyor, we have the right solutions for your requirements. Application-optimized rolling bearings from XKTE master all challenges: Heavily different temperatures, moisture, dust, dirt, as well as noise and vibration reduction.

About US:

Shandong Xinkaite Bearing Co., Ltd. is a professional belt conveyor roller bearing manufacturer enterprise, specialized in manufacturing bearings for the bulk material handling industry and supply all kinds of conveyor idler components. our bearings are being used in multiple applications including: mining machinery, carrying idlers and reverse rollers as well as drum pulley. Our factory is located in Yandian of Liaocheng in mainland China, covered an area of 18,000 square meters, registered trademarks "XKTE".

And there are many long-term fixed partners of ours within the areas centered by conveyor roller bearing industry. With our company`s gradually growing, from the rough to the bearing, we set up a one-stop production line, with 50000 pieces produced every day on our automated production lines. all products are manufactured according to GB standards or in compliance with your specific requirements.

Our Service:

1. Volume production and large Inventories, stable quality

2. OEM is supported

3. Small order accept

4. Various Brands

5. Wide Array of Applications

6. Fast delivery

7. Our company insists on the "quality first, credit first" business ideas and our product specification is well-founded. We have a good reputation in the international market by our perfect service and sufficient supply.

Packing

Product Categories : Conveyor Components > Conveyor Idler Components